Home > Information > News

#News ·2025-01-07

With all the hype around generative artificial intelligence (AI) in industry, it seems like almost every day a new buzzword pops up. What's the latest buzzword? The term "Industrial AI Agent," also known as an industrial AI Agent, has almost no standard definition in the industrial world, but the definition is close: an industrial AI agent is a flexible and powerful software entity capable of intelligently representing and managing the functions and capabilities of an industrial organization. Simply put, when trained with the right data and the right AI model, industrial AI agents can perform specific tasks in a human-like manner.

The operating co-pilot everyone is talking about or the chatbot you use when trying to rebook a flight are examples of various types of AI agents. They are designed to automate or streamline specific or restricted workflows to improve user productivity. However, today's intelligent platforms that use limited pre-programmed logic are not comparable to future agents based on generative AI.

If we take inspiration from the movies, AI seems to be getting closer and closer to Iron Man's "Jarvis" intelligent assistant, a super-powerful virtual agent that communicates via voice commands to help Iron Man do his best. While we are far from this type of cross-functional intelligence (due to the risk-free, high-reliability nature of industrial operations), the technical building blocks and standards that exist today enable the development of specific and trusted industrial AI agents for specific operator domains.

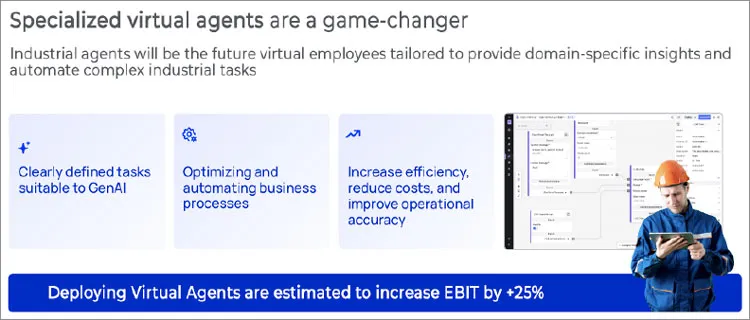

Figure 1: Industrial AI Agents provide automation and intuitive access to information

Figure 1: Industrial AI Agents provide automation and intuitive access to information

For decades, industrial solution providers have been trying to use data and AI to optimize production, minimize the risk of disruption, streamline production, and make smarter day-to-day decisions. But unfortunately, so far, the impact on plant floor operations has been less than satisfactory.

The way users interact with digitally enhanced industrial processes is not intuitive, making it challenging to actually improve key workflows and achieve productivity gains. Technologies that do not significantly improve workflows will not be widely adopted.

While in flight, if Iron Man can't talk to Jarvis and he has to manually look up information using precise terminology, his workflow (and mission outcome) suffers. In the field, the operator workflow is precise and mature. Information must be trustworthy and instantly accessible, using handheld devices and simple commands, rather than relying on lines of SQL code.

Generative AI provides a better interface to complex data (when built and accessed under the right conditions). While operators may not be able to ask their AI the same range of questions as Iron Man, their answer interface is becoming more human and intuitive than ever before, which allows it to be incorporated into the workflow.

How did Iron Man build the Jarvis Assistant? While we don't know for sure, we can venture an educated guess:

These three parts are critical to properly delivering an industrial AI Agent that you can trust.

As an important part of AIGC, AI Agent and large model carry different functions and effects. So what's the difference?

AI Agent is an intelligent entity that can perceive the environment, make decisions and perform actions. It has the characteristics of autonomy, interactivity, reactivity and initiative, and can play an important role in various practical operation and control scenarios. The core functions of AI Agent include but are not limited to environment perception, reasoning, learning and adaptation, and can be applied in a variety of scenarios.

Large models are machine learning models with large scale parameters and complex computational structures. These models are trained using large amounts of data and computational resources to improve their generalization and accuracy. Large model is widely used in natural language processing, image recognition, speech recognition and other fields, and has achieved remarkable results.

The development of AI Agent pays more attention to the interaction logic between agent and environment, and how to learn and adapt according to environmental feedback. The training of large models focuses on deep learning through large-scale data sets, so the development and training costs are high.

The application scenarios of AI Agent are usually closely related to specific tasks or environments, and can achieve effective interaction with the environment, which is suitable for various practical operation and control scenarios. Because of its extensive knowledge base and processing power, large models have a wider range of application scenarios.

The interaction between the large model and the human is based on the text input by the user, and whether the text input is clear or not will affect the effect of the large model's answer; The work of AI agents only needs to be given a goal, and they can think and act independently on the goal.

AI Agent consists of three processes: perception, decision making and execution, forming a closed-loop feedback system. Large models are open prediction or generation models and do not have a complete closed-loop intelligent architecture.

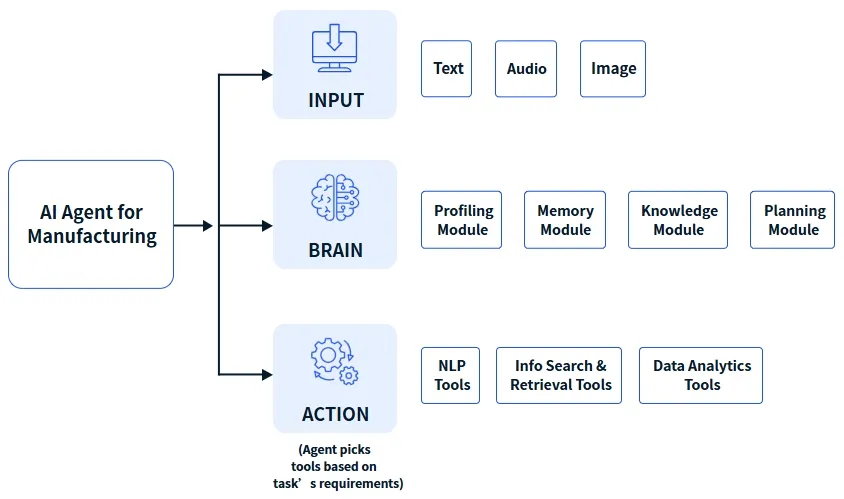

Figure 2: Key components of an AI Agent for manufacturing

Figure 2: Key components of an AI Agent for manufacturing

Input: This component captures and processes a variety of inputs from sensors, machines, and operators, including data in various formats, such as sensor readings, operation logs, and production metrics. These inputs guide the actions and decisions of AI agents, providing real-time insight into the manufacturing process.

Brain: The brain is critical for cognitive function in manufacturing operations and contains several modules:

Action: This component performs the actions within the plan, utilizing the modules of the brain to automate and optimize the manufacturing process. By breaking down complex tasks into actionable steps, AI agents ensure efficient production operations, using specialized tools and equipment as needed.

In manufacturing, AI Agents play a key role in improving operational efficiency, minimizing downtime, and optimizing production outcomes through intelligent data analysis and decision making capabilities.

Data collection and analysis: AI agents are adept at collecting, cleaning, and integrating data from a variety of sources, such as production systems, IoT sensors, supply chain databases, and quality control metrics. They act as data processors and senior analysts, providing forecasting and strategic insights that are critical to operational decisions.

Process automation and optimization: AI Agents in manufacturing go beyond automating routine tasks like inventory management and production scheduling; They also optimize these processes by managing exceptions, errors, and exceptions. By constantly learning and adapting, these AI agents excel at automating complex manufacturing processes such as predictive maintenance, quality control, and supply chain management.

Decision and execution: AI Agents act as experienced decision makers in manufacturing, handling key decisions related to production planning, resource allocation, equipment maintenance, and quality assurance. These decisions are based on powerful data-driven models that ensure efficiency and minimize risk. AI agents can also transparently explain their decisions, thus promoting accountability and trust in manufacturing operations.

Collaboration and communication: AI Agent facilitates seamless communication and collaboration between different departments within a manufacturing organization and with external partners. As centralized interaction platforms, they enhance the collective intelligence of the entire manufacturing ecosystem, ensuring consistency and informed decision making. Conversational AI agents enhance internal communication by facilitating the effective exchange of information and insights between teams to improve operational efficiency and responsiveness.

AI Agents play a key role in transforming manufacturing operations and preparing organizations to effectively address current challenges and future opportunities by automating complex manufacturing processes, enhancing decision-making, and facilitating collaboration between teams and partners.

Building AI agents tailored for manufacturing involves a structured approach that starts with clear goals and ends with continuous optimization. This is a detailed guide to developing AI agents to handle custom tasks and drive manufacturing business growth.

Establish your goals: Before starting development, it is crucial to define your expectations for the AI Agent. Determine if an AI Agent will manage production planning, automate quality control, handle predictive maintenance, or optimize supply chain processes. Understanding your specific needs will guide your approach to building AI agents. If you need more clarification, consider consulting an AI expert for clarity and direction.

Choose the right framework and library: This step is critical to building an efficient AI Agent. Tools such as TensorFlow, PyTorch, and Keras provide powerful platforms for developing machine learning models to process data and make intelligent decisions. For more specialized areas of manufacturing, consider exploring domain-specific libraries that provide pre-built models for industrial analysis. Leveraging frameworks such as CrewAI and AutoGen Studio can facilitate rapid prototyping and integration of AI capabilities, making it particularly useful for deploying complex AI solutions tailored to manufacturing needs.

Programming language of choice: Python remains the top choice for AI development due to its simplicity, flexibility, and the rich ecosystem of libraries and frameworks it supports. Its readability and wide range of applications make it ideal for developing AI agents in manufacturing, where complex algorithms are common. If you use a dedicated framework, these frameworks usually provide their development environment and may support multiple programming languages.

Collecting data for training: The effectiveness of AI agents in manufacturing depends largely on the quality of the data used for training. Make sure your data is high quality, unbiased and clean. This can involve production data, equipment logs, quality control metrics, and supply chain information.

Design basic architecture: The architecture of AI agents should be scalable, modular, and performance-driven. It should also be designed to be integrated so that it can be easily updated and compatible with other systems and technologies. This is critical in manufacturing, where systems must interact seamlessly with production lines, supply chain platforms, and quality management systems. Specialized frameworks typically provide predefined architectures or templates tailored for manufacturing applications. However, you may need to customize the architecture to meet your requirements.

Start model training: Training the model involves setting up the environment, feeding it data, and iteratively improving its decision-making capabilities. Depending on your specific use case, use techniques such as reinforcement or supervised learning. CrewAI and AutoGen Studio may provide specialized tools and environments for training AI models using these techniques. Models are constantly validated and refined to ensure they meet the required accuracy and efficiency standards.

Deployment: Deploy AI Agents using cloud services, containers, or serverless architectures, depending on your operational requirements and scalability needs. Platforms such as Docker, Kubernetes, or AWS Lambda can provide powerful and flexible deployment options. The AI Agent development framework can provide simplified deployment options, such as cloud-based deployment or integration with existing manufacturing systems, which can simplify the deployment process. Ensuring that the deployment environment is secure and adheres to the highest standards of data protection is critical in the manufacturing industry.

Testing: Thorough testing must be done to ensure that the AI Agent is functioning properly in all intended operations without errors or deviations. This includes performance, security, and user acceptance testing to ensure that the AI Agent meets technical specifications and user expectations.

Monitoring and optimization: After deployment, the performance of the AI Agent is continuously monitored to ensure that it ADAPTS to new data and changing manufacturing conditions. Update the system regularly to improve its functionality and expand its capabilities as your business grows. This step is critical to keeping AI agents relevant and efficient in a dynamic manufacturing environment.

By performing these steps, you can develop a powerful AI Agent that can not only automate tasks, but also provide a strategic advantage in the highly competitive manufacturing space. Such AI agents can turn data into actionable insights, improve operational efficiency, and ensure strong quality control, ultimately driving growth and efficiency in manufacturing operations.

2025-02-17

2025-02-14

2025-02-13

friend link

400-000-0000

立即获取方案或咨询

top